Ultimate Mechanical Auto Workshop Safety File Template Kit

R 3,000.00

Description

Overview:

Elevate your auto workshop’s safety standards with our Ultimate Mechanical Auto Workshop Safety File Kit. This meticulously crafted template is designed to meet all your safety documentation needs, ensuring comprehensive coverage and compliance with industry regulations.

Key Features:

- Dual Environment Coverage: Separate sections for Office and Workshop Site environments, providing tailored safety measures across all business operations.

- Detailed Indexing: Every document is indexed for easy access, from company documentation and appointment letters to risk assessments and safety meetings.

- Preparedness: Stay ahead with dedicated COVID-19 documentation, including risk assessments and safety procedures.

- Policies & Procedures: In-depth policies, safe working procedures, and method statements for both office and site environments.

- Training & Meetings: Integrated sections for internal training, toolbox talks, and safety meetings.

- Regulatory Adherence: Stay compliant with detailed sections on OHS Act and other relevant regulations.

Ideal For:

- Mechanical Auto Workshop Safety Compliance: Perfect for companies aiming to maintain top-tier safety standards.

- Business Safety Structuring: Ideal for businesses seeking a structured and detailed safety documentation template.

- OHS Regulations Compliance: Essential for companies wanting to ensure full compliance with Occupational Health and Safety regulations.

What’s Included:

- Comprehensive Office & Workshop Site Environment Safety Documentation

- Editable documents in Microsoft Word and / or Excel formats (soft copies)

- Immediate download access upon payment completion

Why Choose Our Kit?

Our safety file kit is designed to simplify the process of maintaining high safety standards in your auto workshop. With easy-to-edit documents and a user-friendly structure, it’s never been easier to ensure your business meets all safety and compliance requirements.

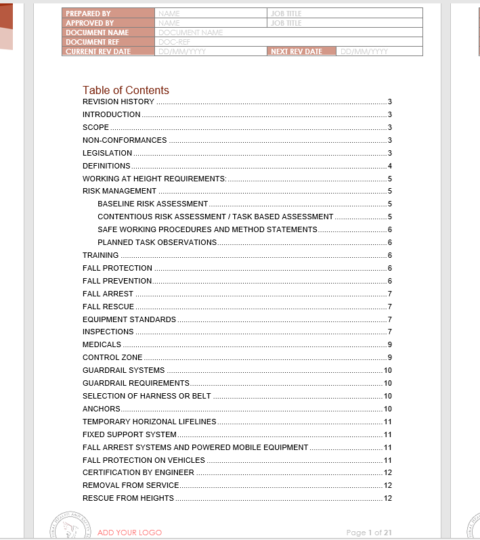

Index (All listed below is included in the kit)

0.Company and Employee Supporting Documentation

0.1 Company Supporting Documentation Insert Company Profile (optional) Insert insurance Documentation Insert legal Registration and Sars Documentation Insert letter of good standing 0.2 Employee Supporting Documentation Insert Medical Records (if use optional) Insert Training certificates Insert workers emergency contact details Insert workers ID's or passports

1.Appointment Letters and Organogram

1.1 Office Environment

Organogram

1.1.0 CEO

1.1.1 Assistant To The CEO

1.1.2 Evacuation Officer

1.1.3 First Aider

1.1.4 Health And Safety Committee Member

1.1.5 Health And Safety Representative

1.1.6 Incident Investigator

1.1.7 Risk Assessor

1.1.8 SHE Committee Chair Person

1.1.9 Environmental Coordinator

1.1.10 Ergonomic Risk Assessor

1.1.11 Facilities Coordinator

1.1.12 Fire Fighter and Inspector

1.1.13 Hygiene Inspector

1.2 Workshop Environment

Organogram

1.2.1 Vehicle and Mobile Plant Inspector

1.2.2 Hazardous Chemical Substances Supervisor

1.2.3 Hand Tool Inspector

1.2.4 Personal Protective Equipment Inspector

1.2.5 Power Tool Inspector

1.2.6 Evacuation Officer

1.2.7 First Aider

1.2.8 Risk Assessor

1.2.9 Fire Fighter and Inspector

1.2.10 Competent Person Supervisor Of Machinery

1.2.11 Assistant To The Competent Person Of Machinery

Proof of Training and Communication to Workers of Appointment Letters and Organogram

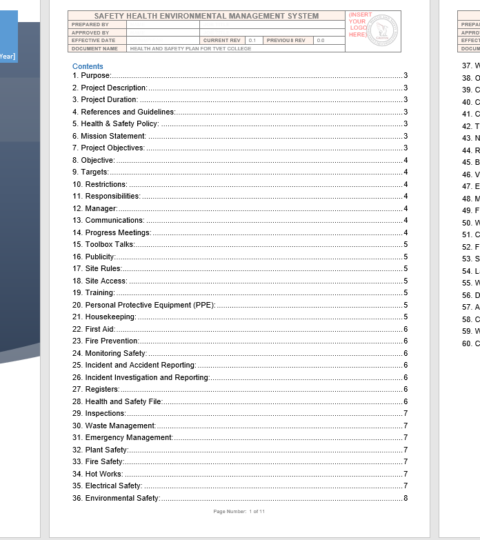

2.Health and Safety Programmes

2.1 Health and Safety Plan 2.2 Business Continuity Programme 2.3 Drug and Alcohol Programme 2.4 Emergency Management Plan Programme 2.5 Housekeeping Programme 2.6 Risk Assessment and Review Programme 2.7 Smoking Programme 2.8 Stacking and Storing Programme 2.9 Toolbox Talks Programme 2.10 Waste Management Programme 2.11 Incident & Accidents Management Programme 2.12 Environmental Programme 2.13 Hazardous Chemical Substance Programme 2.14 Personal Protective Equipment Programme Proof of Training and Communication to Workers of Health and Safety Programmes

3.Policies

3.1 SHE OHS Policy 3.2 Business Continuity Policy 3.3 Drug and Alcohol Policy 3.4 Emergency Management Policy 3.5 Housekeeping Policy 3.6 Risk Policy 3.7 Smoking Policy 3.8 Stacking and Storing Policy 3.9 Waste Management Policy 3.10 Environmental Policy 3.11 Incident Management Policy 3.12 Environmental Policy 3.13 Hazardous Chemical Substance Policy 3.14 Disease & Illness, Covid-19 Policy 3.15 Quality Policy Proof of Training and Communication to Workers of Policies

4.Risk Assessments

Baseline Risk Assessment Office Baseline Risk Assessment Workshop Baseline Risk Assessment Task & Workshop Specific Risk Assessments Angle Grinders, Bench Grinders and Saws Client, Visitor & Public Compressed Air Confined Spaces Diesel or Petrol Dust Generation Electricity, Fire, Explosion, Chemicals Exposure to Noise Falling Objects Fire on Site First Aid Flammable Materials General Chemicals Hand Tools Manual Handling Material Storage Mechanical Workshop Risk Assessment Office Environment – Welfare & Storage Plant and Transport Power Tools Toxic Materials Use of Arc Welding Equipment Use of Portable Electrical Equipment Vehicles Movement On Site Waste Materials Welding Working Alone Proof of Training and Communication to Workers of Risk Assessments

5.Safe working Procedures and Method Statements

5.1 Office Environment Computer Workstation SWP Door Safety SWP Electrical Office Safety SWP Ergonomics Video Display Terminals SWP Fan Safety SWP Fire in Office SWP First Aid SWP General Chemicals SWP General Rules in Office SWP Housekeeping SWP Manual Handling of Office Equipment SWP Moving of Office Furniture SWP Office Environment – Welfare & Storage SWP Paper Cutter Shredder SWP Photocopies Paper SWP Safe Keyboard Use SWP Sharp Objects SWP Stacking and Storage SWP Stair Safety SWP Stapler Safety SWP Unloading of Vehicles SWP Waste Materials SWP Working Alone SWP 5.2 Workshop Environment Angle Grinders, Bench Grinders and Saws Client, Visitor & Public Compressed Air Confined Spaces Diesel or Petrol Dust Generation Electricity, Fire, Explosion, Chemicals Exposure to Noise Falling Objects Fire on Site First Aid Flammable Materials General Chemicals Hand Tools Manual Handling Material Storage Mechanical Workshop SWP Office Environment – Welfare & Storage Power Tools Toxic Materials Use of Arc Welding Equipment Use of Portable Electrical Equipment Vehicles Movement On Site Waste Materials Welding Working Alone Proof of Training and Communication to Workers of Safe Working Procedure Method Statement

6.Registers, Checklists and Inspections

6.1 Checklists and Inspections Daily Handtools Checklist Daily PPE Checklist Daily Vehicle Inspection Checklist Ergonomics Checklist Fire Extinguisher Equipment Checklist Fire Extinguishers Checklist First Aid Box Checklist Housekeeping Checklist Portable Electrical Tools Checklist Workplace OHS Inspection Checklist 6.2 Registers Fire Extinguisher Register Fire Fighting Equipment Monthly Register First Aid Box Register Handtools Register Mechanical Equipment Repairs Log Book Personal Protective Equipment On Hand & Issued Register Power Tools Register PPE Register Stacking and Storage Monthly Register Stacking Vehicle Register Visitor Access Control Register Proof of Training and Communication to Workers of Registers, Checklists and Inspections

7.Toolbox Talks and Inductions

Commandments for Safety Induction with Register Company Safety Rules Induction with Register Multi Toolbox Talks Office Safety Toolbox Talks and Induction with Register Proof of Training and Communication to Workers of Toolbox Talks and Inductions

8.Material Safety Data Sheet (MSDS)’s

Bleach example HANDY ANDY WHITE 120203 example Insert applicable ones here MSDS 008. HANDY ANDY PINK 120203 example MSDS 011. Sunlight Liquid example Proof of Training and Communication to Workers of MSDS's Sunlight Liquid example

9.Permits

Hot Work Permit Proof of Training and Communication to Workers of Permits

10.Training

Record of Training of Office Appointed Structure Training Matrix

11.Covid-19 Safety

COVID-19 Coordinator Appointment COVID-19 Programme COVID-19 Risk Assessment Proof of Training and Communication to Workers of Covid-19 Safety

12.Safety Meetings

Meeting Report Standard Safety Meeting Minutes Standard Safety Register

13.Daily Safety Task Instruction (DSTI)

DSTI Awareness Training DSTI Register DSTI Template

14.Disciplinary

Disciplinary Discharge Letter Disciplinary Final Warning Disciplinary Investigation Disciplinary Warning Form Disciplinary Written Warning Notification Of A Disciplinary Investigation

15.Legislation, WCL and Annexures (Free)

Driven Machinery Regulations, 1988 Environ Reg for Workplaces, 1987 Ergonomics Regulation 2019 Facilities Regulations 2004 General Administrative Regulations, 2003 General Safety Regulations, 1986 Occupational Health and Safety Act

Note : If you require any additional documentation you can’t find here, let us know and we can compile it for you. Email us: info@grisk.co.za

You must be logged in to post a review.

Reviews

There are no reviews yet.